Wiring Smart Pixels

The most important part of your show is the wiring. This heavily affects the cost, ease of setup/take down, and how easy it is to fix problems. It is important that you thoroughly understand wiring, before you choose how you want to layout your show.

Basic Recommendations

First, let me list some of the basic recommendations as a starting point for your display.

1) Only drive fifty 5Vdc pixels without power injection (assumes standard 60mA per pixel).

2) Only drive one hundred 12Vdc pixels without power injection (assumes standard 60mA per pixel).

3) Do not use ground loops in your power.

4) Use Ethernet cable, a twisted pair, for control signals (control/ground)

5) Multiple small controllers around the yard minimize wiring and cost.

6) Finally, you should be able to measure the current to your strings and determine the voltage at the end of a string. For pixels without internal regulators the voltage drop at the end of the string should be no more than 10%, 4.5Vdc for 5Vdc and 10.8Vdc for 12Vdc. The maximum voltage drop for strings with built in regulators depends upon the minimum input voltage for the regulator, so check the specifications for your specific pixels.

Wiring Methods

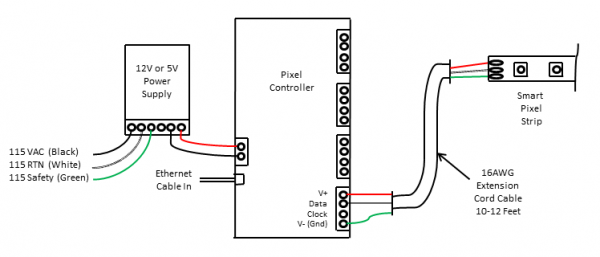

Direct Power

By far the least expensive method to drive smart pixels is with a large power supply powered through your controller. The only other components required is a power cable to the pixels. It is recommended that you use 16AWG extension wire in lengths of 10-15 feet, which is cheapest bought as an extension cord. The only cost for this layout is the controller, large power supply and the wire.

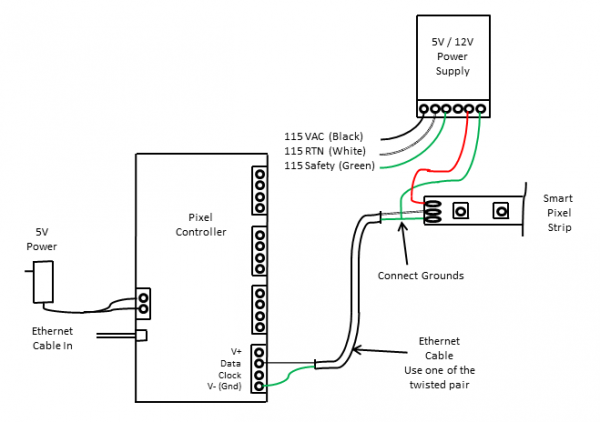

Local Power Supply

If the pixels are further away from your controller, it is best to use a local power supply and Ethernet cable for the control lines. If you use Ethernet cable to drive the control signals, with 100 ohm source termination, it has been demonstrated to work to at least 100 feet. The drive chip used was an 74ACT541 versus the standard 74HCT541. The ACT parts have more current drive, which will improve your ability to drive the signal further. The local power supply adds some additional cost for power.

Local Power Supply with Pixel Extender

In electronic engineering, best practice for signals that go more than a couple feet is to add a differential driver/receiver pair (RS-422/485). These drivers make the signal more immune to noise and allow the signal to be driven further. For pixel data rates (approximately 1MHz), the expected distance is 1000 feet. These also add the benefit of allowing the ground between your lights and controller to vary up to ±7Vdc. By far this is one of the best methods to drive strings. It will always work at any distance, the input to the display element is an Ethernet cable and power is through an extension cord. There are a couple controllers available with pixel extenders built in. This adds additional cost for the buffer/receiver boards.

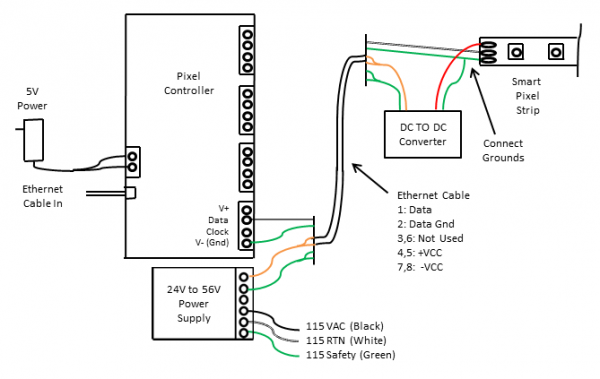

Power Over Ethernet

This method allows you to use one cable for both power and control lines. The power over Ethernet specifications is written for use with 48Vdc and 56Vdc power supplies at 600mA maximum current. The higher the voltage, the longer you can make the cables with out any issues. For use with 5V and 12V strings without the DC to DC converter, you need to check current in the cable and voltage at the last pixel. This method is not recommended for 5V pixels.

This is really best used with two power supplies, a high voltage power supply at the controller and a small DC to DC converter at each string. The high voltage on the cable minimizes the current required to drive the lights. For example, if you have a string of 50 - 5Vdc pixels, the current at the string is 3 amperes maximum (power = voltage x current) or 15 watts. The amount of current varies with the voltage as shown below:

12V = 1.25 amperes

24V = 0.625 amperes

36V = 0.417 amperes

48V = 0.313 amperes

The Ethernet jacks are rated at 1.5 amperes, and normally two pins are used. Nominally for commercial equipment the connectors are derated by 15 percent to 3.0 x 0.85 = 2.5 amperes. This would be the peak current through the cable.

When choosing a DC to DC converter make sure that the module can support 3 amperes of continuous current. The LM2596 is a good example of what not to buy, it supports 3 amperes peak, with 1 ampere of continuous current.

Power Over Ethernet with Pixel Extender

This is just a repeat of the above version with pixel extenders. This adds the benefits as previously mentioned of distance and ground variance.

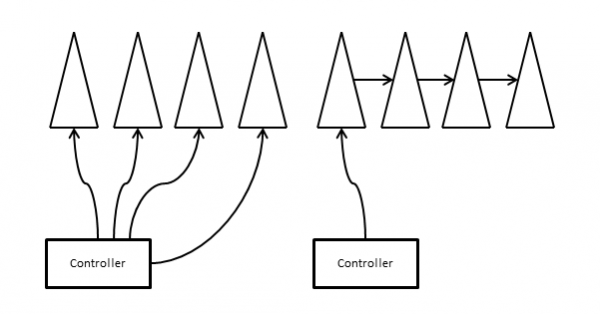

Wiring and Controllers

Another aspect of wiring to consider is the type of controller you buy. A controller may support 1 to 4 universes of lights or 170 to 680 pixels per output. So this would affect your layout of your wiring. For example, in the picture below, you can wire four mini-trees with each using one output, or all four using the same output. The first version allows you to use a common power supply if the trees are close, and the second requires power to be injected into the string.